bend test procedure|guided bend testing equipment : manufacturer The procedure for conducting a bend test using a Universal Testing Machine (UTM) can be broken down into the following steps: Test Preparation: This involves preparing the test . WEBea sports fc online. 로그인. game start. 열기

{plog:ftitle_list}

Resultado da 7 de jan. de 2024 · Casa da Mãe Joana, #124 entre Franca pubs & bares: 811 avaliações e 74 fotos detalhadas. Encontrar no mapa e ligar para reservar .

The procedure for conducting a bend test using a Universal Testing Machine (UTM) can be broken down into the following steps: Test Preparation: This involves preparing the test .ASTM E290-22. Standard Test Methods for Bend Testing of Material for Ductility. Significance and Use. 5.1 Bend tests for ductility provide a simple way to evaluate the quality of materials .What is a Bend Test? The bend test is a fundamental and versatile materials testing method used to assess the ductility, flexibility, and strength of a material. The test provides insights into a material's toughness and ability to resist .

ASTM E290 A-26, ISO 7438 I-8, and JIS Z2248 J-5 are some of the general standards which describe the requirements for the bend testing of metals. In a Three-Point Bend Test, a .

welding bend test procedure pdf

A bend test, also known as the flexural test, is a standardized method employed to assess the ductility, bend strength, fracture strength, and resistance to fracture of materials. This testing methodology involves subjecting a specimen to a .Bend tests are conducted to determine the ductility or strength of a material. This article discusses the different bend tests with emphasis on test methods, apparatuses, procedures, .Bend Testing 101. How much or how little a material will bend can determine its suitability for use in a product or structure. A bend test measures flexural strength, strain or stress to find out whether that material is a good choice for .A bending test (bending tensile test) is a method of testing materials for their bending strength and other important properties. Destructive materials testing is used for plastics, fiber-reinforced plastics (FRP), metals and ceramic materials.

B1. Longitudinal Guided-Bend Test (See Part A1, section 7.6, Fillet Weld Root Bend Test.) 1. Scope 1.1 This section covers the bend testing of fillet welds. The standard gives the requirements for guided bend test specimen preparation, test parameters and testing proce-dures, but does not specify the requirements or accep-tance criteria. ASTM D2344 bend test xture. ASTM C1161 bend tes ng xture. ASTM C158 Bend T es ng – Glass. . following custom tes ng procedures that may r equire non-standard equip-ment.Bend Test Process and Procedure. The bend test requires using a mandrel with a diameter measuring at least four times the thickness of the sample. The sample with the coated surface is placed in a vise with the coating facing outward and bent over the mandrel until its two legs are parallel. Bend the specimen back and forth repeatedly through .

before or after bending) or dressing bent specimens, will result in the immediate loss of bend testing privileges and failure of the welders. Approx 180º . Acceptable Bend Test Unacceptable Bend Test . The CWB Group ontinue towill c perform the evaluation of the bend test specimens.ASME Section IX Bend Test This article provides information about ASME Section IX bend test requirements. Based on the ASME Code Section IX, we need to perform two tensile tests, two root bend tests and two face bend tests with the satisfactory result to be able to qualify our welding procedure specification.. The ASME Section IX Training Course is 2 days video .A cracked or fractured specimen documents failure.. In reporting Bend-testing for weld qualification, it is important to specify location of the specimen on the weld test panel, and direction of weld with reference to the bend radius.. Bend-testing is therefore a procedure capable to separate quality weld specimens from defective ones.. The confidence in the .

THREE-POINT BENDING TEST PROCEDURE: RECTANGULAR CROSS SECTION. 1. Determination of the stiffness (compliance) of the testing system: K. s (C. s). The test is carried out applying the load to the specimen supported on a rigid surface. The stiffness is determined in the linear zone, when the curved zone due to indentation effects dissappears. It .Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is .

Bend test. Buy. Follow. Table of contents. Foreword. 1 Scope. 2 Normative references. 3 Terms and definitions. 4 Symbols, designations and units. 5 Principle. 6 Test equipment. . The procedures used to develop this document and those intended for its further maintenance are described in the ISO/IEC Directives, Part 1. In particular, the . The bend test is specified in ASME section 9 and AWS D1.1 for welder testing & weld testing for performance & procedure qualification. 2. . FREE-BEND TEST FOR WELD TESTING. Free Bend Test measures the ductility of the weld metal in a butt joint in a plate or pipe in terms of elongation percentage. The thickness of the specimen is the same as .Mechanical test methods that are applicable to welds and welded joints are described. For each testing method, informa- . procedure to be followed, and report requirements are also described. ISBN: 978-0-87171-889-1 . bend tests, fracture toughness tests, hardness tests, break tests (nick and fillet welds),

The BEND TEST! One of the tests used to determine the soundness of weld metal is a bend test. . Bend Tests are used for evaluating welds for welder performance qualification testing, welding procedure qualification, and product sampling. Bend tests may bend the weld towards the face, towards the root, or sideways. The most common is a guided .A 10-year follow-up evaluation about the effectiveness of school screening for scoliosis shows that Adam’s forward bend test has a sensitivity of 84.3%, a specificity of 93.44% for a cobb angle >10° but the authors of the study concluded that the forward bend test alone was ineffective for detecting scoliosis, owing to the high number of .

As stated previously, radiographic testing may be used in lieu of bend tests. Procedures, technique and acceptance criteria for this type of test is provided in Clause 8 (Inspection) of AWS D1.1/D1.1M:2020 Structural Welding Code – Steel (Clause 6 if you are still using the 2015 edition). The test procedure, as well as the test tubes used for bend testing of the butt welded joints, are defined by the Standard EN 910 (Welded butt joints in metallic materials-Bend test) [3].

Small-scale bending tests (Fig. 7) provide a simply fixable set-up for anchors characterization in combined shear-bending and even in equilibrium critical application.It is probably the closest combination of stresses to simulate a real-scale bended structure, which is possible through a small-scale test [97].In this case, recovery of characterization data from the .

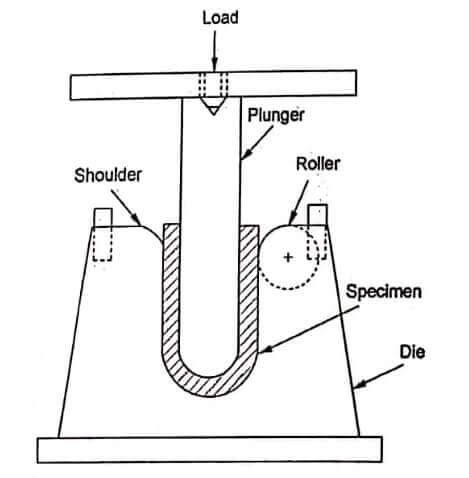

Flexural stress at break: The flexural stress at which a specimen breaks during a bend test. For some materials, the specimen breaks before a yield point, in which case the flexural strength equals the flexural stress at break. Test Method. .Bend testing is a procedure to determine the relative ductility of metal that is to be formed (usually sheet, strip, plate or wire) or to determine soundness and toughness of metal (after welding, etc.). . Bend Test. A Bend Test may be carried out on a tensile testing machine with the help of certain attachments and fixture. The bend test . The bend usually is made using a radiused plunger that pushes the sample down into a radiused female die. Q: Sometimes I make aluminum bend test samples that bend only 30 or 40 degrees and then snap. What's going on? A: This isn't uncommon in aluminum bend tests. A sample that has broken this way is shown in Figure 1. The sample started to bend .Three-point Bend Test procedure and working is derived from the theory of bending of the simply supported beam as explained above. To carry out the calculation of the test results after conduction of the 3-point bend test, one needs to rely on the theory of bending of the beam.

The dimensions for root bend test are given in ASME Section 9 QW-462.3 (a) is used to determine if the weld meets the requirements for this test. Face bend test. The transverse face bend test is a specimen loaded from the weld root side so that the weld face side become convex. Appendix B - Penflex U-Bend Test Procedure . Penflex Test Report: U-Bend Fatigue Test Page 11 of 11 Appendix C - Picture of Penflex U-Bend Tester . Title: Test Summary Report Author: Daniel Vitek MBA, PMP - Consultant to CDC NCPHI Subject: Keywords: CDC Unified Process, CDC UP, CDCUP How to Prepare Bend Test Coupons for a Pipe Welding Certification. Preparing of the test coupons was done following the AWS B2.1 welding certification procedure notes. How to Mark Weld Test Coupons on a Pipe. First I marked the pipe with a template. The template marks the pipe from the 1 o'clock to 12 o'clock positions.

types of bend tests

#welddotcomToday we are going to show you how to pass a bend test with the plate bender we built. If you're a welding student or professional welder chances . The root bend test is a welding test in which the weld root is on the convex surface of a specified bend radius. This test is used to evaluate the mechanical and metallurgical properties of a weld joint. The root bend test is often used in qualification tests for welding procedures and welder performance. The root bend test can be used to . A special machine is used to perform the guided bend test. The material must be able to bend up to a specific angle, such as 180 degrees, without any cracks appearing. If this happens, the weld has passed the test. No reversal of the bend force is employed when conducting these tests. Types of bend tests include: Guided-bend test; Semi-guided .ASTM flexural test refers to testing procedures governed by ASTM standards, such as ASTM D790 for plastics, ensuring consistent and comparable results across laboratories. What is the difference between a flexure test and a bend test? While both assess a material’s behavior under bending, the flexure test quantifies specific properties like .

ul325 drop test

transverse vs longitudinal bend test

Lorrana Joyce Assistir no capetinhas.blog videos gratis da novinha Lorrana Joyce mostrou buceta gostosa passando a mão da pepeca. LorranaJoyce ( @lorranajoyce ) .

bend test procedure|guided bend testing equipment